HSM Jet Spindle – Testing the Difference

Colibri is helping machining professionals around the world to reduce machining time, increase tool life, boost productivity and cut overall operating costs. The test report data has been collected under live operating conditions for a range of applications that serve numerous industries: Die & Mold, Fine Machining, Medical, Energy, Automotive, Aerospace and more.

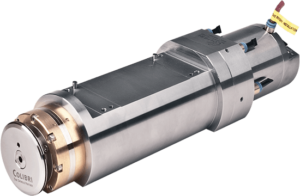

GreenJET & HPC JET – Test Reports

The latest Test Reports using the GreenJET & HPC JET Spindle models show a dramatic reduction in machining time compared with the machine spindle + many other important benefits.

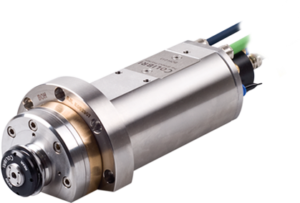

HPC Jet Spindle – Case Studies

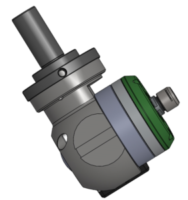

Customers seeking to increase productivity using the power of high pressure coolant pumps. The HPC (High Pressure Coolant) Jet Spindle was tested at several customer facilities.

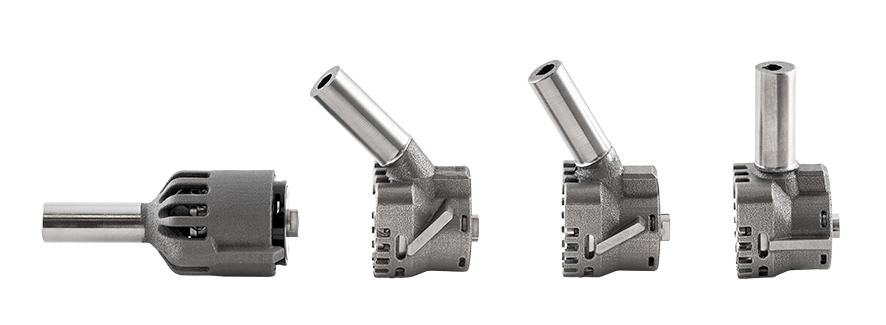

Jet Spindle 20K/30K – Case Studies

Customers the world over want to speed up machining processes for a better bottom line. The HSM Jet Spindle was tested at numerous customer facilities with impressive results.